มอเตอร์สเต็ปแบบแม่เหล็กถาวร 2 เฟส 4 สาย ขนาด 25 มม. ใช้ในอุปกรณ์สำนักงาน

คำอธิบาย

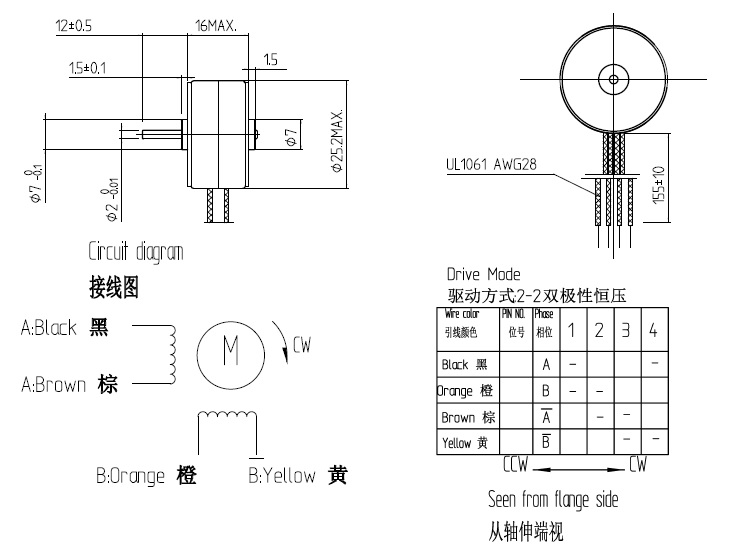

มอเตอร์ตัวนี้มีเส้นผ่านศูนย์กลาง 25 มม. และความหนา 16 มม. เส้นผ่านศูนย์กลางของเพลาส่งกำลังของมอเตอร์คือ 2 มม. ความยาวสามารถปรับแต่งได้ตามความต้องการของลูกค้า เพลาส่งกำลังของมอเตอร์สามารถปรับแต่งเพื่อติดตั้งแกนสกรูและเฟือง แกน D เพลาแบนคู่ ฯลฯ ซึ่งสามารถปรับแต่งได้ตามความต้องการในการติดตั้งของลูกค้า

สำหรับการติดตั้งมอเตอร์ สามารถผลิตแผ่นยึดที่มีหูยึดได้เช่นกัน

ทีมงานของเรามีประสบการณ์มากกว่า 10 ปีในการออกแบบ พัฒนา และผลิตมอเตอร์สเต็ปเปอร์ ดังนั้นเราจึงสามารถพัฒนาและออกแบบผลิตภัณฑ์ตามความต้องการพิเศษของลูกค้าได้!

พารามิเตอร์

| แรงดันไฟฟ้า | 5ดีซี |

| จำนวนเฟส | 2เฟส |

| มุมขั้นบันได | 157% |

| ความต้านทานการพันขดลวด-25℃) | 8Ω±10% |

| ระยะปัจจุบัน | 0.625A |

| แรงบิดล็อค | 110 กรัม.ซม. |

| อัตราการดึงสูงสุด | 300PPS |

| แรงบิดยึด | 120 กรัม.ซม. |

| แรงบิดดึงออก | 200pps/30g.cm |

| อุณหภูมิการพันขดลวด | 65,000 บาท |

| ความแข็งแกร่งของดิดเลคทริก | 600 VAC 1 วินาที 1 mA |

แบบร่างการออกแบบ: เพลาส่งกำลังสามารถปรับแต่งได้

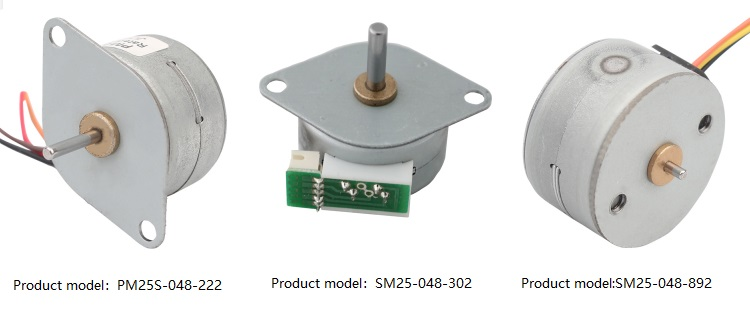

มอเตอร์ประเภทเดียวกัน

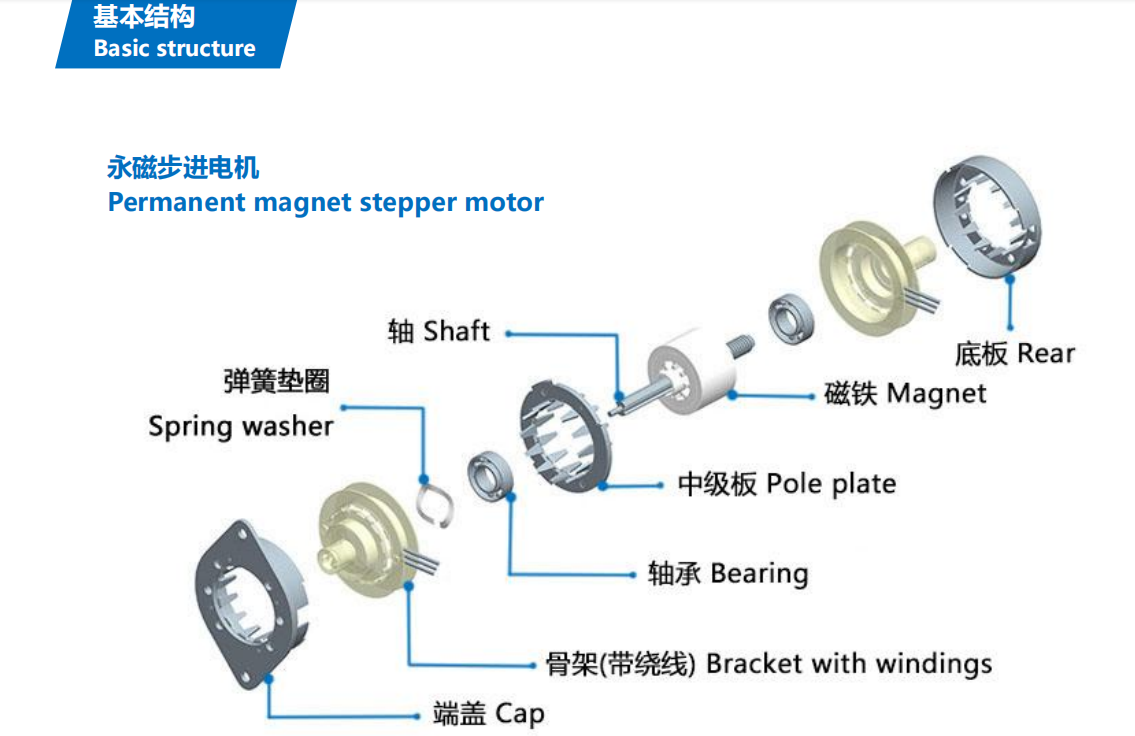

เกี่ยวกับโครงสร้างพื้นฐานของมอเตอร์สเต็ปเปอร์ PM

คุณสมบัติและข้อดี

1. การกำหนดตำแหน่งที่มีความแม่นยำสูง

เนื่องจากสเต็ปเปอร์มอเตอร์เคลื่อนที่ด้วยขั้นตอนที่แม่นยำและทำซ้ำได้ จึงเหมาะอย่างยิ่งสำหรับการใช้งานที่ต้องการความแม่นยำสูง

การกำหนดตำแหน่ง โดยพิจารณาจากจำนวนก้าวที่มอเตอร์เคลื่อนที่

2. การควบคุมความเร็วที่มีความแม่นยำสูง

การเคลื่อนที่แบบเพิ่มทีละน้อยอย่างแม่นยำยังช่วยให้สามารถควบคุมความเร็วในการหมุนสำหรับกระบวนการได้อย่างยอดเยี่ยม

ระบบอัตโนมัติและหุ่นยนต์ ความเร็วในการหมุนถูกกำหนดโดยความถี่ของพัลส์

3. ฟังก์ชันหยุดชั่วคราวและค้างจังหวะ

ด้วยการควบคุมไดรฟ์ มอเตอร์จะมีฟังก์ชันล็อค (มีกระแสไฟฟ้าไหลผ่านขดลวดมอเตอร์ แต่

มอเตอร์ไม่หมุน) และยังคงมีแรงบิดยึดอยู่

4. อายุการใช้งานยาวนานและมีสัญญาณรบกวนทางแม่เหล็กไฟฟ้าต่ำ

มอเตอร์สเต็ปเปอร์ไม่มีแปรงถ่าน และไม่จำเป็นต้องใช้แปรงถ่านในการสลับกระแสเหมือนมอเตอร์แบบมีแปรงถ่าน

มอเตอร์กระแสตรง (DC motor) ไม่มีแรงเสียดทานจากแปรงถ่าน ทำให้มีอายุการใช้งานยาวนานขึ้น ไม่มีประกายไฟ และลดการรบกวนทางแม่เหล็กไฟฟ้า

การประยุกต์ใช้มอเตอร์สเต็ปเปอร์ PM

เครื่องพิมพ์

เครื่องจักรสิ่งทอ

การควบคุมอุตสาหกรรม

เครื่องปรับอากาศ

หลักการทำงานของมอเตอร์สเต็ปเปอร์

การขับเคลื่อนของมอเตอร์สเต็ปเปอร์ถูกควบคุมด้วยซอฟต์แวร์ เมื่อมอเตอร์ต้องการหมุน ระบบขับเคลื่อนก็จะทำงาน

ส่งสัญญาณพัลส์ไปยังมอเตอร์สเต็ปเปอร์ สัญญาณพัลส์เหล่านี้จะจ่ายพลังงานให้กับมอเตอร์สเต็ปเปอร์ตามลำดับที่กำหนดไว้

ทำให้โรเตอร์ของมอเตอร์หมุนไปในทิศทางที่กำหนด (ตามเข็มนาฬิกาหรือทวนเข็มนาฬิกา) เพื่อที่จะ

เพื่อให้มอเตอร์หมุนได้อย่างถูกต้อง ในแต่ละครั้งที่มอเตอร์ได้รับพัลส์จากไดรเวอร์ มันจะหมุนด้วยมุมหนึ่งขั้น (ในระบบขับเคลื่อนแบบเต็มขั้น) และมุมการหมุนของมอเตอร์จะถูกกำหนดโดยจำนวนพัลส์ที่ส่งมาและมุมหนึ่งขั้น

ระยะเวลานำส่ง

หากเรามีสินค้าตัวอย่างในสต็อก เราสามารถจัดส่งตัวอย่างได้ภายใน 3 วัน

หากเราไม่มีสินค้าตัวอย่างในสต็อก เราจำเป็นต้องผลิตขึ้นมาใหม่ ซึ่งใช้เวลาในการผลิตประมาณ 20 วันทำการ

สำหรับการผลิตจำนวนมาก ระยะเวลานำส่งขึ้นอยู่กับปริมาณการสั่งซื้อ

บรรจุภัณฑ์

ตัวอย่างสินค้าจะถูกบรรจุในฟองน้ำและกล่องกระดาษ จากนั้นจัดส่งโดยบริการจัดส่งด่วน

ในการผลิตจำนวนมาก มอเตอร์จะถูกบรรจุในกล่องกระดาษลูกฟูกโดยมีฟิล์มใสห่อหุ้มด้านนอก (จัดส่งทางอากาศ)

หากขนส่งทางทะเล สินค้าจะถูกบรรจุลงบนพาเลท

วิธีการชำระเงินและเงื่อนไขการชำระเงิน

โดยทั่วไปแล้ว สำหรับการส่งตัวอย่างสินค้า เรารับชำระเงินผ่าน PayPal หรือ Alibaba

สำหรับการผลิตจำนวนมาก เรารับชำระเงินผ่านการโอนเงินทางธนาคาร (T/T)

สำหรับการส่งตัวอย่างสินค้า เราจะเรียกเก็บเงินเต็มจำนวนก่อนเริ่มการผลิต

สำหรับการผลิตจำนวนมาก เราสามารถรับชำระเงินล่วงหน้า 50% ก่อนการผลิต และเรียกเก็บเงินส่วนที่เหลือ 50% ก่อนการจัดส่ง

หลังจากที่เราร่วมมือกันสั่งซื้อสินค้ามากกว่า 6 ครั้ง เราสามารถเจรจาเงื่อนไขการชำระเงินอื่นๆ ได้ เช่น การชำระเงินเมื่อเห็นเอกสาร (A/S - After Sight)